I am sure you already heard those insane claims of people: Katana folded over 1000 times. That’s complete nonsense. In this article, I want to show you how many times katanas are folded in reality.

Let’s get right to it. How many times are Katanas folded? Katanas are usually folded between 8 and 16 times.

There is a specific reason why people say that their katana is folded over 1000 times. Read along and we will unveil the myths about folded steel katanas.

Table of Contents

What is Folded Steel?

First things first, folded steel isn’t a steel type like carbon steel. Folded steel is a forging technique applied to mostly carbon steels (10xx series).

The process is mostly self-explanatory. As the name states, the metal is forge welded, folded and welded again.

Why are Swords Folded?

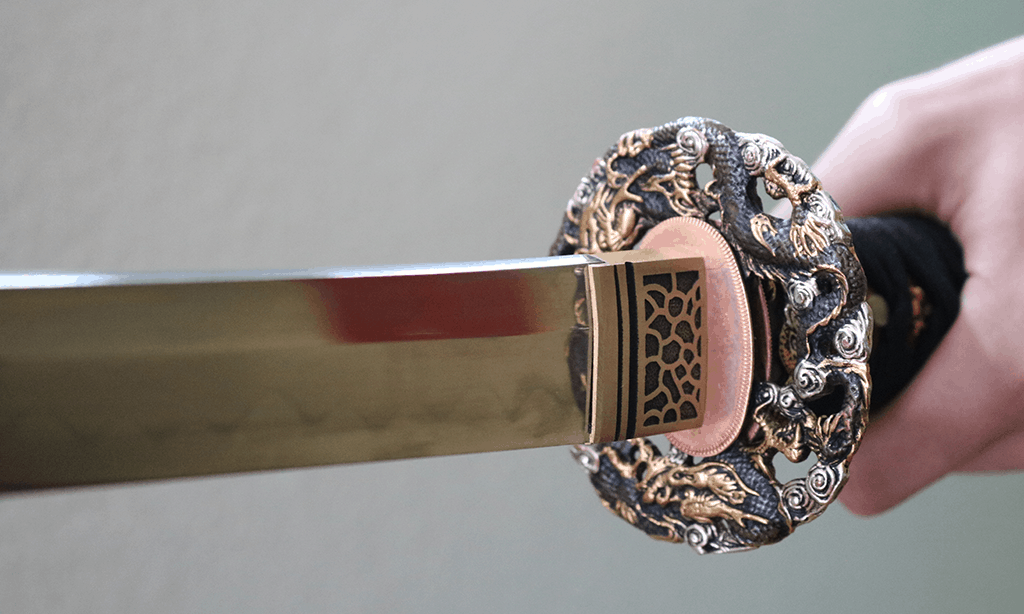

Most Japanese swords were folded. Here I want to give you a quick history lesson. In case you aren’t interested just move on to the next part of the post.

Most iron deposits in Japan contain ore with very high carbon content. This iron was called Tamahagane or pig iron.

As this steel contains 4-5% of carbon it is unsuitable for blade forging. This carbon content would make every sword break extremely easily.

So, the Japanese swordsmiths had to come up with a solution to this problem. They discovered the process of folding steel.

Thereby, they could remove the impurities in the steel and reduce the carbon content.

What are the Effects of Folded Steel?

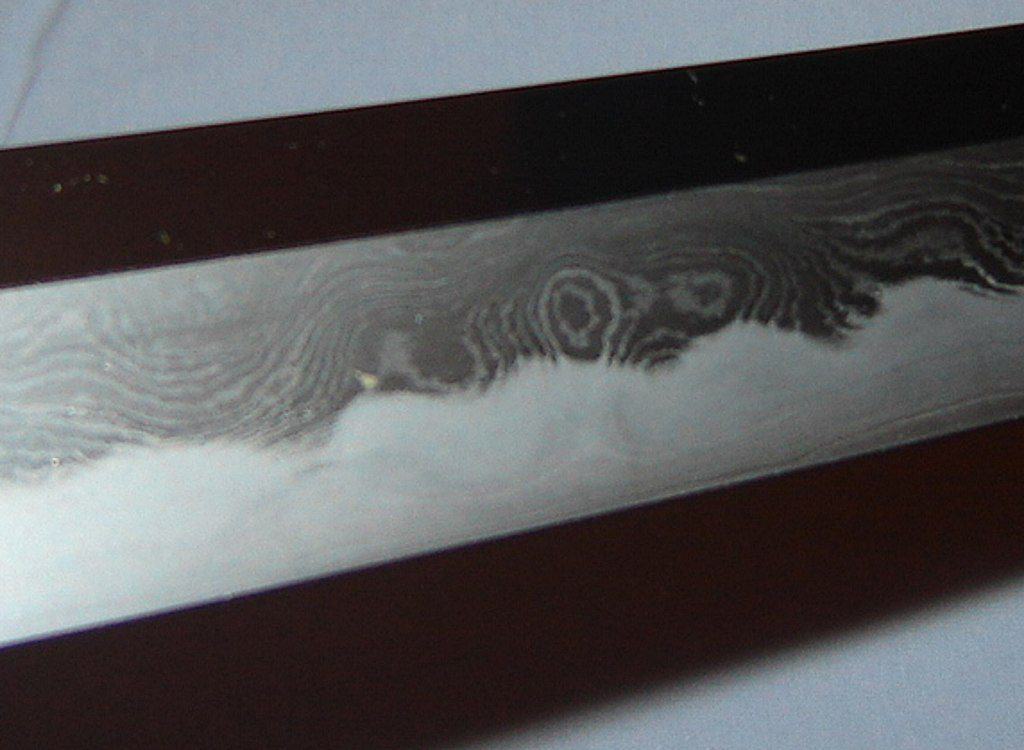

Every time the steel is folded you create more and more overlapping layers. These alternating layers greatly enhance the toughness of the blade.

Furthermore, they add to the unique design of a katana. Everyone can spot a katana by one of its prominent features, one of it being the layers created by the folded steel.

How many Folds does a Katana have?

Ok, this is the part where it gets tricky. Don’t worry it confused me in the past as well. However, I think I came up with a great explanation for this process.

Let’s compare steel folding to folding a sheet of paper. You start with a single layer. When folding it once you have two layers. Folding again results in four layers.

The next time you fold the paper you have 8 layers, 16 layers, 32 layers, 64 layers and so on. You see each time you fold the paper/steel the number of layers doubles.

The same principle applies to folded steel. After folding a blade 10 times you have 1024 layers. Folding 16 times results in 65 thousand layers.

This is the reason why people say their katana is folded 1000 times. Those people are confusing the number of folds with the layers created.

Undoubtedly a lot of online stores do that. A blade which was folded 65 thousand times sounds way more impressive than a 16 times folded one.

After all this is just a huge marketing/promotion trick. Even if the shop owners “artificially” increase their folding counts this confuses a lot of people. Furthermore, I really hate this approach as the stores just lie to their customers.

Conclusion

I came up with the idea to write this article because most online stores “cheat” when stating their steel fold count.

This leads to a lot of confusion on the customer side and makes it difficult to compare the correct data with the incorrect one.

Store A has a sword that was folded 16 times for example. However, Store B advertises their katana which was “folded” 1024 times.

Someone who doesn’t know how folding steel works might be enticed to buy from store B, although store A might have a better offer (and a blade which was folded more often).

That’s quite a pity. I hope that I could reach a lot of people with this article and shed some light on this common misconception about katanas.