The 10xx series is probably the most used steel variety for sword and knife making. Among these, 1095 carbon steel is a popular choice.

Whilst, not used as much in European swords a lot of katanas are forged from this steel.

In this article I will umedienveil how good the AISI 1095 carbon steel really is and tell you interesting facts on its properties, forging, tempering and care. So, stay tuned :D

Table of Contents

1095 Steel Classification in SAE System

Like most steels, the 1095 carbon steel is classified in the SAE system. I’ve covered this topic in more detail in my Sword Steels Complete Guide.

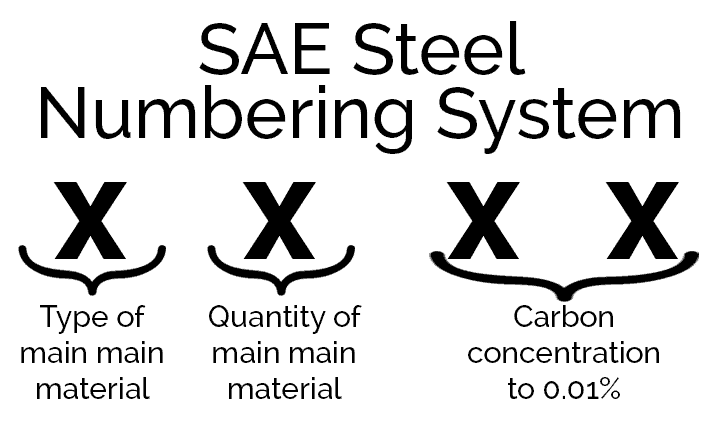

Here are the basics you need to know right now. Every steel in the SAE system is represented by four-digit numbers. Each of those digits represents a specific property of the steel.

The first numeral indicates the type of main material. The following table shows you all the different steel types.

| 1. Carbon steel | 2. Nickel steel | 3. Nickel-chromium steel |

| 4. Molybdenum steel | 5. Chromium steel | 6. Chromium-vanadium steel |

| 7. Tungsten-chromium steel | 8. Nickel-chromium-molybdenum steel | 9. Silicon-manganese steel |

For sword making the materials 1, 5 and 9 are relevant. The second digit indicates the concentration of the major element in percent.

The last two digits of the series stand for the carbon concentration to 0.01%.

1095 Steel Properties

By now you might have realized that 1095 steel is forged from carbon. It has a carbon content of around 0.95%. This steel type is similar to tamahagane which was traditionally used in Japan to forge katanas.

Due to its high carbon content 1095 steel is considered high carbon steel. Furthermore, it contains around 1.2% of manganese.

This alloying agent gives the steel some extra strength and flexibility. In case you need more detailed and technical information regarding the properties of this steel check out this website.

As we now know the composition of this steel type, it is time to check its performance.

1095 Steel Performance

A lot of katanas are forged from 1095 steel. This isn’t only due to historic reasons, but also because this steel type is perfectly suited for test cutting (tameshigiri).

Other steel varieties of the 10xx series such as 1045 or 1060 are often considered too soft. (Of course, this also depends on the use case)

However, you need to be aware that the carbon increase of 0.35% from 1060 to 1095 steel makes an enormous difference when talking about hardness and strength.

1095 has an exceptionally high carbon content making the blade extremely hard. I’ve had great fun doing tameshigiri with my 1095 katana.

Moreover, this steel is a great choice for differential tempering. Typically done on katanas this is the process of creating a harder edge and a softer spine.

During this forging phase, the characteristic hamon line of the katana is created. That’s another reason why 1095 or 1060 steel so often used when forging a katana.

That’s only aesthetics, but no one can deny that a hamon line looks great on katanas.

The impressive hardness of a 1095 blade offers even more advantages. Such a sword is able to take and keep a way sharper edge than one with lower carbon content.

However, 1095 carbon steel doesn’t only have advantages. Each of the aspects mentioned before also causes some downsides.

Resulting from its incredible hardness the sword becomes more brittle. The high carbon content makes the blade very rigid.

The sword is unforgiving if being wielded improperly. I mostly recommend a 1095 steel blade to advanced swordsmen.

It doesn’t have great impact resistance, thus it might shatter if your edge alignment isn’t spot on.

Therefore, proper heat treatment becomes extremely important. This plays a big role in increasing the low durability of the sword.

A differentially tempered blade also has a higher toughness than a mono tempered one.

Another disadvantage caused by the high carbon levels is the low corrosion resistance. In my eyes, this is only a tiny problem as it can be solved easily.

You just have to keep your sword clean and oil it regularly. More on the topic of caring for a 1095 steel blade is at the end of this article.

However, if you don’t look after your sword from time to time it might rust extremely quick. This steel is prone to rust, but if you follow my tips this will hopefully not happen to you.

In terms of price, a 1095 steel sword or katanas is in the mid-tier. On average a good sword costs around 400€.

Keep in mind not to buy those swords really cheap, as you want a quality heat treatment. Especially with this steel correct tempering is the most important aspect that decides whether the sword is good or bad.

I really want to stress this point. Heat treatment is vital for all swords, but with such high carbon content, it becomes of utmost importance.

I will now cover the use cases of 1095 steel for katanas and swords.

1095 Steel for Katanas

Whether or not you want to actually use your sword a 1095 katana looks extremely good. It can create a very nice and prominent hamon line, which is great for collectors.

The entire 10xx series is extremely often used when forging katanas. This is because its properties perfectly resemble the characteristics of steel used centuries ago to forge traditional katanas.

This particularly applies to the 1095 steel. It is probably the closest you will come to an authentic katana steel in a decent price range.

For these reasons, I like to recommend clay tempered 1095 carbon steel to collectors. However, this sword steel is also great for practical use.

It is just incredible for tameshigiri. With a sharp 1095 katana, you will have a lot of fun cutting. Due to its good edge retention and taking very sharp edges, it will slice the mats with ease.

Remember that you want a differentially tempered katana for more durability. The extra price will definitely pay off.

1095 Steel for Swords

This steel type wasn’t traditionally used for forging European swords. If you want this steel for your sword I would say go for it.

You’ve already read the pros and cons of 1095 carbon steel. It is now up to you to make a decision. If you ask me I wouldn’t recommend you 1095 high carbon steel sword.

If you’ve read more of my blog posts, you certainly have realized that I am a fan of spring steel. Just take a look at my Sword Steels Complete Guide.

Spring steel offers a way more durable sword. When talking about medieval European swords I prefer durability over hardness.

In my opinion, medieval swords should be forged from 5160/9260 as they offer great benefits. Furthermore, they fit the historical context really well.

1095 Steel Endurance

As you might have already realized the durability of 1095 steel swords is extremely low. They shatter very fast.

Correct edge alignment when cutting is enormously important. Otherwise, you might shatter or dent your blade.

Hitting your sword against a wooden stand, for example, might already cause it to shatter. You need to be very careful.

I’ve already done a lot of cutting with my 1095 katana and it never broke. However, this might also be due to great heat treatment and differential tempering.

Keep in mind not to buy a low-quality sword. By buying one which is more expensive you receive a better heat treatment which increases durability.

Furthermore, differential tempering helps a lot to further increase durability.

How good is 1095 steel?

How good is 1095 steel? That’s a question I get asked a lot. Based on everything I mentioned you can decide on your own. In the following, I will give you my personal opinion.

The SAE 1095 carbon steel is my go-to choice for katanas. It is perfect. This steel type has a great cutting ability.

In case you are a beginner a 1045 or 1060 steel katana is also a great choice. They are a bit cheaper as well.

Regarding medieval/European swords I can’t recommend this steel type. If you know what you are doing certainly go for it!

However, in my opinion, it doesn’t really match the characteristics of medieval swords. Even if you want to do some cutting with your sword I would recommend looking into spring steel.

I really love spring steel, it offers great durability at a reasonable price. For this reason, I would pick a 5160/9260 steel for medieval swords.

So to conclude this 1095 steel is extremely good for katanas. However, it is not as good for medieval swords.

How to heat treat 1095 steel?

A friend of mine asked me how to heat treat a 1095 steel blade a few days ago. Therefore, I decided to add this topic to my blog post.

AISI 1095 carbon steel can be heat treated at 899°C. Thereafter it is quenched in oil, brine or water. This step has to be performed extremely fast. Otherwise, the blade will form pearlite.

Now you need to let your sword cool down to around 50°C. Then you want to temper your sword at around 210°C. Repeat the tempering process one more time.

Tempering duration should be around 2 hours. Using this strategy hardens the edge to around HRc66.

As you might already know you can differentially temper the blade by covering the spine with clay.

1095 Steel Sword Care

A blade with such a high carbon content needs proper care. This is extremely important if you don’t want your sword to rust.

Other steel types don’t rust as quick. 1095 really is prone to rust. You should polish your sword at least once every three months.

If you used your sword you should clean it immediately of course. Cleaning a 1095 steel blade is identical to other steels.

First, you need to wipe the blade in order to remove dust, fingerprints, water and other particles. Then you need to apply a thin layer of oil to your sword. This greatly increases rust resistance.

If you want to store your sword for a long time you might want to use Renaissance Wax. I have never used it myself, but it is said to be extremely good. Museums use this wax for preserving their precious items as well.

Conclusion

I hope you got everything you wanted to know about 1095 carbon steel.

Concluding it can be said that this steel is the perfect choice for katanas if you already have experience with sword-wielding.

For medieval swords, I prefer to use spring steel due to its added durability.

If you have any questions, make sure to ask them in the comments. I’ll try to answer every question I can!